As automation in general continues to proliferate in factory environments, so too does the role of...

The 4 Pillars of Industrial Network Support

Is your network ready for planned upgrades to your automation, drive, and data systems?

Even if you are not moving toward the newest trends in the industry, like the Industrial Internet of Things (IoT), cloud computing, Big Data, and Industry 4.0, your automation systems are likely in need of an upgrade. Whether to replace obsolete equipment, improve speed and accuracy of production, or to better integrate the plant floor with the main office, upgrading means staying relevant in your industry.

Your industrial communication network should be on the top of the upgrade list. It is this network that will ultimately impact hardware and software upgrades.

The essential aspects of modern industrial network support lie outside the specifics of protocols and data speeds. Of primary importance is taking a high-level view of the network from the standpoint of the eventual control and business needs.

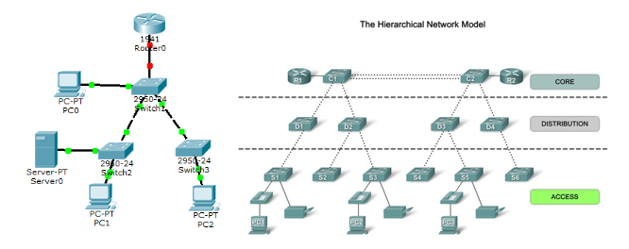

A careful network design is imperative. If a flat network is allowed to expand without restraint, it can soon reach a point where errors are passed on to a large part of the plant. Further modification becomes time-consuming and expensive.

Four issues that impact industrial network support of operations, and the plant as a whole, should be considered: linking of IT and automation, component selection, redundancy, and diagnostics.

1. Connecting IT with Automation

These two areas of almost every manufacturing business can have vastly different perspectives. This is evident in the differing network components and topologies utilized. Regardless of these differences, modernization means that the networks of both areas must be reviewed.

Components and topologies must support the mechanisms and protocols needed for the production system as well as for IT. For example, there may be a need for support of command line interfaces and 10 GB transmission rates for devices on the border of IT and production networks.

2. Comprehensive Selection of Components & Security

The practice of purchasing based on price continues to permeate the industry, but modernization requires a more holistic approach. Added value, created by updating technology, cannot be compared through sale price alone. Component interaction, environmental conditions, energy savings, and high availability are all attributes that can realize large savings over years, but are often not considered at the point of sale or beginning of the project.

Applying this approach to security is essential. Control system and network security is complex. Not only must it be well planned, but it must be consistently practiced by the user. When it comes to security, the best approach may be to utilize the expertise of an external company, as it is common to develop blind-spots due to existing policies and procedures.

3. Protection through Redundancy

Network faults are always a possibility, even in carefully planned and maintained systems. Production up-time and system wide safety can be gained by installing corresponding redundancy mechanisms. These mechanisms enable the industrial network to ride through and/or recover from failures in components or cables, without affecting the communication.

Many components already support a variety of redundancy protocols, so implementing redundancy does not necessarily mean higher costs. Since redundancy can be implemented in various ways, an attention to design is needed to satisfy network requirements.

4. Transparency and Diagnostics

Industrial networks are typically under constant restructuring, either by adding/removing devices or linking existing systems with each other. It then becomes imperative to maintain thorough documentation of your network: a task which cannot be adequately performed manually. Modern network management systems are available, which can monitor and document the network structures including identification and maintenance data. Weak points in the network can be quickly located and networks can be more easily expanded and optimized.

Adding or implementing diagnostics often appears to be just another added cost, as an immediate added value is not obvious. The value appears in reduced or eliminated downtimes due to network failures. Diagnostic tools that continuously monitor the network are more readily available and easily implemented and should be utilized to correct problems before they lead to failures.

To fully leverage diagnostic capabilities, it is important to use mechanisms that can be integrated into your existing automation and HMI/SCADA systems. Then it can be ensured that messages and fault notifications are visible and acted upon in appropriate time.

Industrial Network Support: The Human Element

Whether you're maintaining a network, upgrading, replacing parts, or expanding into new technologies, knowledgable support specialists are the ultimate resource. If you'd like to learn more about the best practices and technology for industrial network support or have an upcoming project you'd like to discuss, talk to an expert at ACD.

You may also be interested in reading:

- Two Easy Clicks for Great Diagnostics at your HMI

- Share Data Between Profibus and Profinet Networks with the S7-1200

- Tracing Within a Siemens PLC