Electromagnetic induction, the principle of the operation of the transformer, was discovered...

Building Energy Efficient Control Panels

For many industrial companies, energy is one of the biggest expenses they have to burden, and even though control panels are a vital component to any process plant, their potential to offer energy savings is often overlooked. Energy-efficient motors use less electricity, run cooler, and often last longer than NEMA (National Electrical Manufacturers Association) B motors of the same size. Here are some of the top advantages of energy-efficient control panels.

5 Advantages for Energy Efficient Control Panels:

- Less internal heating means decreased panel cooling requirements

- Increased overall energy savings for the end user

- Less power required from the utilities = less natural resources required for power generation

- Reduced power grid consumption means there is no need to build new power plants

- Potential energy savings rebate money available to the end users (contact ACD for details)

How to Start Building More Energy-Efficient Control Panels:

Start by taking advantage of the new technologies with energy-efficient hybrid motor starters and universal control coils in conventional contactors, which also allow a wider range of control power options without changing coils.

Hybrid Motor Starters:

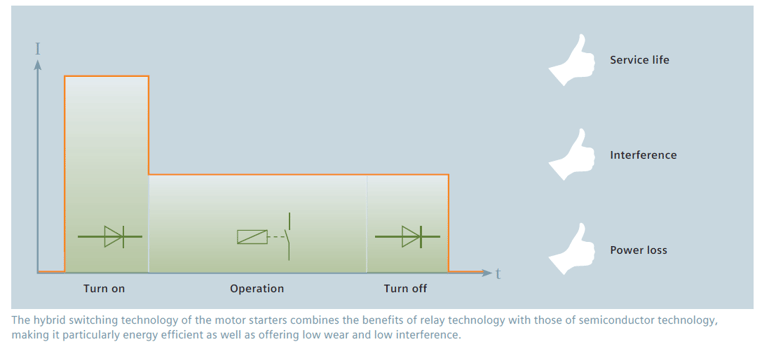

When it comes to hybrid motor starters, switch-on and switch-off are based on solid-state switching technology, while relay technology is applied during the operating phase which allows the end user to reduce panel cooling requirements. This will save you money and reduce your overall production costs.

Related: Start-up with a small footprint – the Siemens SIRIUS 3RM1 Motor Starter

One advantage that the hybrid motor starters ensure is minimum contact wear and long life while reducing panel size requirements. On the other hand, the hybrid motor starters facilitate energy savings of up to 75% when compared to convention contactors and overload assemblies

SIRIUS Innovations Power Products by Siemens:

Compared to the legacy line control products, these IEC-rated Motor Starter Protectors (MSPs), contactors, and solid-state overload relays provide a considerable reduction in intrinsic power loss and power consumption.

- Contactors with Universal Coils (UC) reduce the coil-holding power consumption by up to 92%

- The use of a 3RB3 Solid-State Overload Relay results in an intrinsic power loss reduction of over 98% when compared to Thermal Overload Relays

- Through enhanced thermal design, intrinsic power loss reductions between 10 - 20% can be realized in the 3RV2 MSPs and Solid State Thermal Overload Relays. This results in lower surface temperatures and reduces MSP power loss up to 40% by choosing the higher overlapping motor current setting range.

BONUS !!

- The 3RB3 Solid-State overloads provide circuit protection for overloads, phase unbalance, phase failure, and ground faults.

- Universal Solid State Coils can be AC or DC, driven with a wide range of voltage options making spare parts management a lot easier